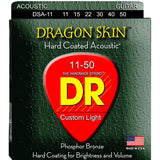

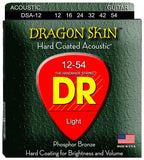

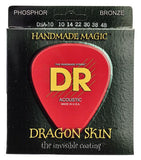

DR Dragon Skin Coated Phosphor Bronze Acoustic Guitar Strings

Product Description

Dragon Skin™ acoustic guitar strings with K3™ Technology

MADE IN THE USA!|

Dragon Skin™ Acoustic Strings WIN the 2018 Product Excellence Award

|

DR Strings has received a 2018 Product Excellence Award from Music Inc. for their DRAGON-SKIN™ Coated Acoustic Guitar Strings. The Excellence Awards are voted on by retail peers who selected products that were “home-runs” in 2018. |

|

K3 Clear Coated Acoustic Phosphor Bronze Strings "sound as good or better than uncoated strings." Dragon Skin sets feature coating on all strings, including the brass-plated steel trebles for extra volume and warmth. The K3 coating is the first coating that players report, "sounds as good or better than uncoated strings." DR's remarkable and proprietary K3 Technology coating is the first coating that makes no apologies and no excuses for not delivering sound equal to uncoated strings. Players tell us that these strings have more volume, less unwanted overtones, greater clarity and articulation than standard, uncoated strings. Yet, they provide the same protection due to corrosion and perspiration as well as increased tone life that coated strings are known for. |

PRODUCT SPECS

String Length: 38"

Material: K3 Clear Coated Phosphor Bronze. Hexagonal Core Wire with Ball End.

| Catalog # | Style | E | B | G | D | A | E | SKU |

|---|---|---|---|---|---|---|---|---|

| DSA-10 | Extra Light | 10 | 14 | 22 | 30 | 38 | 48 | 6-00781-00383-4 |

| DSA-11 | Custom Light | 11 | 15 | 22 | 30 | 40 | 50 | 6-00781-00381-0 |

| DSA-12 | Light | 12 | 16 | 24 | 32 | 42 | 54 | 6-00781-00382-7 |

| DSA-12/56 | Bluegrass | 12 | 16 | 24 | 34 | 45 | 56 | 6-00781-00411-4 |

| DSA-13 | Medium | 13 | 17 | 26 | 34 | 45 | 56 | 6-00781-00384-1 |

| DSA-10/12 | 12 String | 10/10 | 14/14 | 24/9 | 30/12 | 39/18 | 48/28 | 6-00781-00399-5 |

PRODUCT DEMO

THE DR STRINGS STORY

THE FINE ART OF FINE TUNING™

In 1989, DR Strings re-introduced hand-made round core string making to the general market. It requires a lot of skill, time and care, but we feel it’s worth it because we can hear the difference between a handmade string and a machine made string.

If we can hear it, of course players will hear it.

SETTING STANDARDS

TRAINING CRAFTSMEN

Our winders take at least 6 months to learn their craft. It takes that long to develop a feel, an understanding, an instinct to make the constant tiny adjustments that only a hand can make. At each stage we test the wire, we check that it is pristine when it arrives from our suppliers, we inspect each and every wrap during production to ensure its perfect, and then again as we hand-package it.

MADE IN USA WITH ONLY AMERICAN MATERIAL

HIGHEST QUALITY

We use only the finest American materials starting with the wire, to the ball ends, to the packaging.

When someone sees the DR logo, that is what they are getting, the best of everything.

When you put DR strings on a guitar, you’re not only looking for the response of a fresh string,

you’re looking to hear something extra that you didn’t hear before, and that’s our goal…to give you more.

DR was born from guitars. Al Dronge, the founder of Guild Guitars, always wanted to add a string making facility.

Mark Dronge took the lessons he learned from his father and applied them to DR.

DESIGN & INNOVATION

ALWAYS IMPROVING & INVENTING

We are players at DR and we are encouraged to come up with new ideas. In our testing lab, we experiment and design unique and different strings. Quietly, we have been one of the most innovative string companies out there.

We guarantee that players will hear and feel the difference when they play DR handmade strings.

We can’t guarantee that you will like the difference…we hope players do.

This is one of the reasons why we make so many models, for a small company.

We listen and we understand what the players are after and we go for it.